SCOPE OF PROJECT

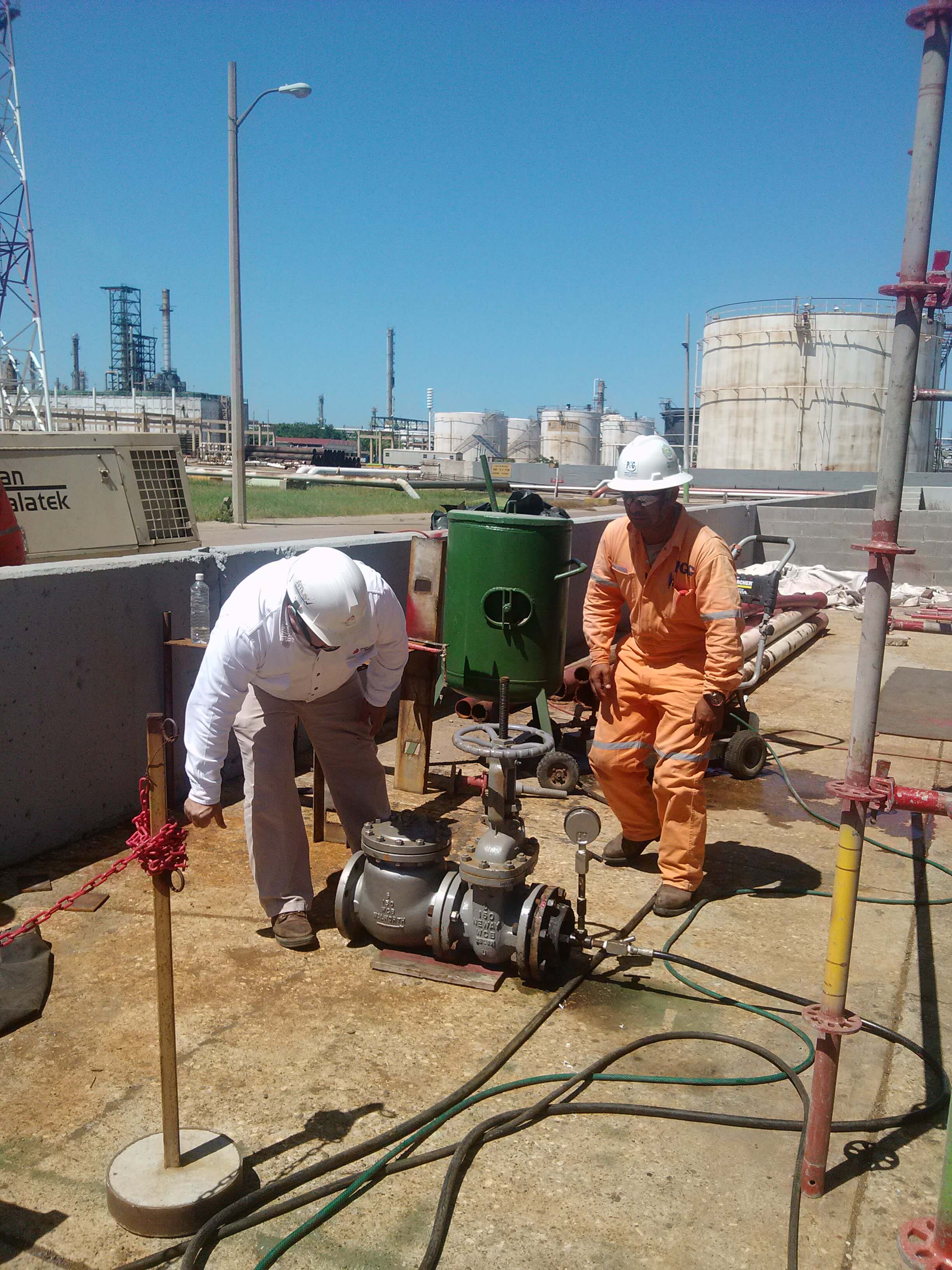

- Extraction and final disposal of wasted mud, settled in the interior of the tank.

- Cleaning and evaporation inside the tank with solvents to eliminate piled waste sediments.

- Dismantling of pipelines of different diameters, of the 5th and 6th ring of the envelope, dome and bottom plate, by using truck-mounted cranes.

- White-metal sandblast cleaning inside and outside the tank, upper face of the bottom, dome and pipelines of different diameters.

- Manufacturing, rolling, alignment and beveling of the bottom plate, the envelope and the dome.

- Mounting, shaping, plumbing, levelling and ticking of plate welding and accessories for the restoration of the tank.

- Provision, handling, and erection of straight pipelines of different diameters, as well as their accessories.

- Application of corrosion protection inside and outside the tank, upper face of the bottom, dome, and pipelines of different diameters.

- Hydropneumatic test with vacuum box and penetrating liquids in the bottom of the tank.

- Butt welding in carbon steel pipelines of different diameters, as well as the joints which are integral part.

- Radiographic inspection of weldings of the tank according to what is stated in the API-Standard-650 code.

- Calibration of body plate thickness and accessories of fixed dome, vertical, cylindrical tank using the ultrasonic method.

- Pneumatic test in tank dome.

- Preparation of report of verticality, peaking, banding and roundness of the tank after its recovery according to what is stated in API-650.

- Installation and commissioning to 100% indicator of temperature, bimetallic and fixed angle.

GALLERY:

|

TYPE OF WORK: Civil Work CUSTOMER: PEMEX TRANSFORMACIÓN INDUSTRIAL PLACE: CD. MADERO, TAMAULIPAS CONTRACT NUMBER: DCPA-OP-SCAR-SASIPA-GPA-I-19-15 |

|

TAGS:

Home

Home

Services

Services Projects

Projects Contact

Contact